Linear Bearings vs. Rotary Bearings: The Essential Differences and When to Use Each

Parts and products related to machinery, engineering, construction, and other heavy industrial usage benefit from using linear bearings. These are the key additional components that are needed especially in the industry, and have a crucial meaning for any process to function without problems. Rotary bearings, on the other hand, come into play in a variety of settings where precision is essential, such as medical devices and laboratory equipment. However, these two mechanisms are of crucial importance and that is exactly why we are talking about them today. What are the essential differences between these two types of bearings? When should you use each type? These are the most common questions to which we have an answer today.

Linear bearings are found in applications that require precision – such as in machinery and engineering parts. Precision is needed in many processes, so it is important to use this type of mechanism to be according to the principles of operation. As we said above, we are talking about very important mechanical elements that are first of all used in the industry for the production of equipment and machines, and then they are also used in other segments that are part of the industries for manufacturing and working with machine devices. We can see in fact that these two types of mechanisms are huge, so from there, we see the point of giving more information and answers.

For all of you who want to get more important information regarding this topic, in the following, we bring you more detailed explanations, but we also bring you more information about when each of the two mechanisms is used. Are you ready to learn more? In that case, follow us to the end of today’s article and learn much more. Let’s get started!

Key differences and uses of these mechanisms in industry and day-to-day functioning

To begin with, we would like to introduce you first of all to the key differences that apply to these mechanisms in industry but also everyday life. Given that the differences exist, we will show you all of them today in the continuation of this article.

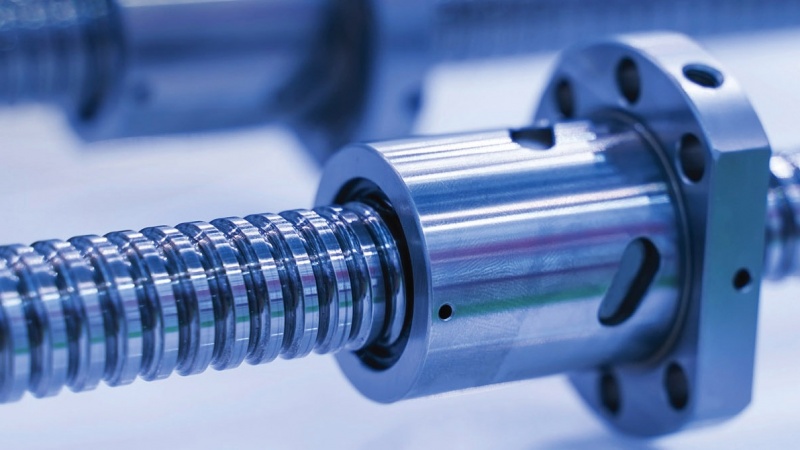

Linear bearings are typically found in heavier applications where precision and stability are key qualities

These bearings use a sealed ball or roller that sits inside a race, with the motion of the wheel directly impacting the angle at which the ball is forced into contact with the race. This geometry results in very low loads being transmitted through the bearing, which makes them great for situations where high load-carrying capacity is not required. If we have to talk about quality, a huge number of people are satisfied with a linear motion by Tuli which are worth it and is recognized as one of the best quality on the market. Therefore, when choosing any of your needs, try to make the right choice.

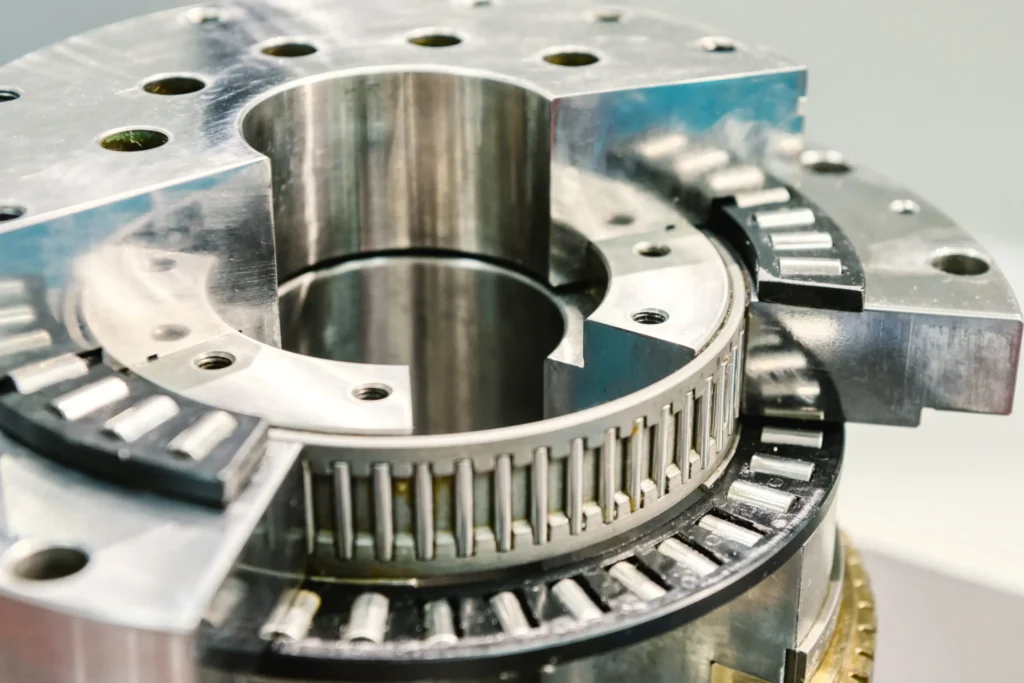

Rotary bearings rely on a pair of spinning balls that are attached to a shaft

The motion of these balls causes them to move along an axis, which then forces them against each other. This part is perfectly designed and thought out and by itself can contribute to easier and better processes in the industry, but also in general in the completion of obligations. Often the culprit for that is the best quality linear bushing, which is very important. This interaction creates a high amount of load transfer through the bearing – perfect for applications that require high speeds and torque. One example of that is car engines that work literally on the same principle. As you can see, there are many reasons why these two types of bearings are so popular – so now it’s time to dive into detail about each type!

Advantages of linear bearings that you must know

- When we talk about linear bearings, one of their biggest advantages is their low load capacity. This means they are known for their ability to reduce vibration and noise.

- They have very low friction rates making them ideal for applications that require continuous motion. One example of this is the ventilation systems that are based on such mechanisms.

- They have excellent overall speed, which means they can handle higher loads with less wear than rotary bearings. This is an advantage that is a huge joy and benefit for many industrial facilities.

Weaknesses of linear bearings that are very important

- Extreme conditions do not favor them, that is, they do not give perfect performance in such conditions, which means that it can limit your work.

- They wear out relatively quickly, which means that in a large number of production and industrial facilities, this would not be beneficial during operation.

- They can be very noisy when handled and worked in an environment that is not ideal for them, such as rooms with a lot of dust or rooms that are dirty – this does not work in favor of these mechanisms.

Positive aspects of rotary bearings that you should know

- First, they have an excellent load capacity that makes them perfect for industries where larger volumes and larger body weights are required to handle these systems.

- They are difficult to abbot which makes them the choice of a large number of industrial complexes where something like this is needed in production or processes.

- Smaller vibrations are emitted by these systems, which makes them much more favorable than the previous ones at certain times of operation.

Disadvantages of rotary bearings that you should also know today

- They need to be used in ideal conditions to achieve the desired performance and result – this is a very important part that everyone should be familiar with.

- It is important that they are from extremely high-quality manufacturers and brands because that is the only way you will be able to get the most out of them.

- It is of crucial importance to place and use them in a clean space in which they would not be damaged and have less performance.

Conclusion

Today we have brought you the most important information you need to know about these two types of mechanisms that will be of crucial importance to you. These details will help you to make the right choice and also to find out all the advantages that these mechanisms could afford you during work and functioning during operation.