5 Ways Robots Are Transforming The Construction Industry

When someone says “robot”, the first thing that might come to mind is an artificial ‘being’ that can carry out numerous tasks. This is, of course, completely true and one of the main reasons why various industries worldwide choose to implement them in their facilities. However, the one industry that uses these devices the most is, perhaps, construction.

If you are thinking about how they entirely changed this industry for good or if you are a business owner thinking about implementing one or two of them on their site, this article can help. The text below will feature some of the ways robots are changing the construction industry, as well as a few benefits that you can gain from implementing them. Let’s take a closer look:

1. Various Processes Are Automated Now

The very first thing on our list is that they can allow the automation of a wide range of processes. When we look at these facilities, more specifically, manufacturing, packing, & building, automating the processes is slowly – but surely – becoming an objective of many processes.

With all the advancements in the AI field, development facilities are now more open-minded when it comes to implementing this tech. With these automated devices, you can entirely expect some orthodox activities like welding, packing, material handling, cutting, and packing to be taken care of and automated. This will help you with being more precise and accurate, and it will save you both time and money.

2. Higher Quality Manufacturing And Building

While most systems are automated, creating parts and processing materials will be more consistent, but more importantly, it will be in higher quality. By taking out man-made mistakes, the machines you choose can be more fast and efficient, and they’ll be able to manufacture continuously, which means that you can produce a large number of parts for a short time.

3. Glazing Robots Made Glass Installation Easy

Are you working on a glass installation project that incorporates you setting large pieces of glass safely and efficiently? If so, you should know that glazing robots can help. Not only will they be able to carry and lift heavy items, but, they can successfully and without problems carry delicate things like glass, screens, and doors.

When dealing with such objects and materials, precision is the most important thing and these devices are entirely capable of doing just that. Additionally, these processes mostly require repetition, which is something they can deal with properly. If you want to see which one you can hire or lease for your company, check out Central Platform Services for more info.

4. They Can Be Used For Demolition

If you have been working in the construction industry for some time, then you know that one of the earliest things robotics was used for is demolition. Just think about how many construction projects are currently being done, and if you manage to speed up the demolition of an object, you can save a lot of cash and time in return.

For instance, breaking down buildings & walls, crushing stone, concrete & other materials, as well as picking up the debris that was left are only some of the things these automated machines can help you with. They’ll manage to speed up the process and with these AI devices, you are hindering the possibility of an employee being injured in the process.

5. They Are Efficient For Smaller Projects as Well

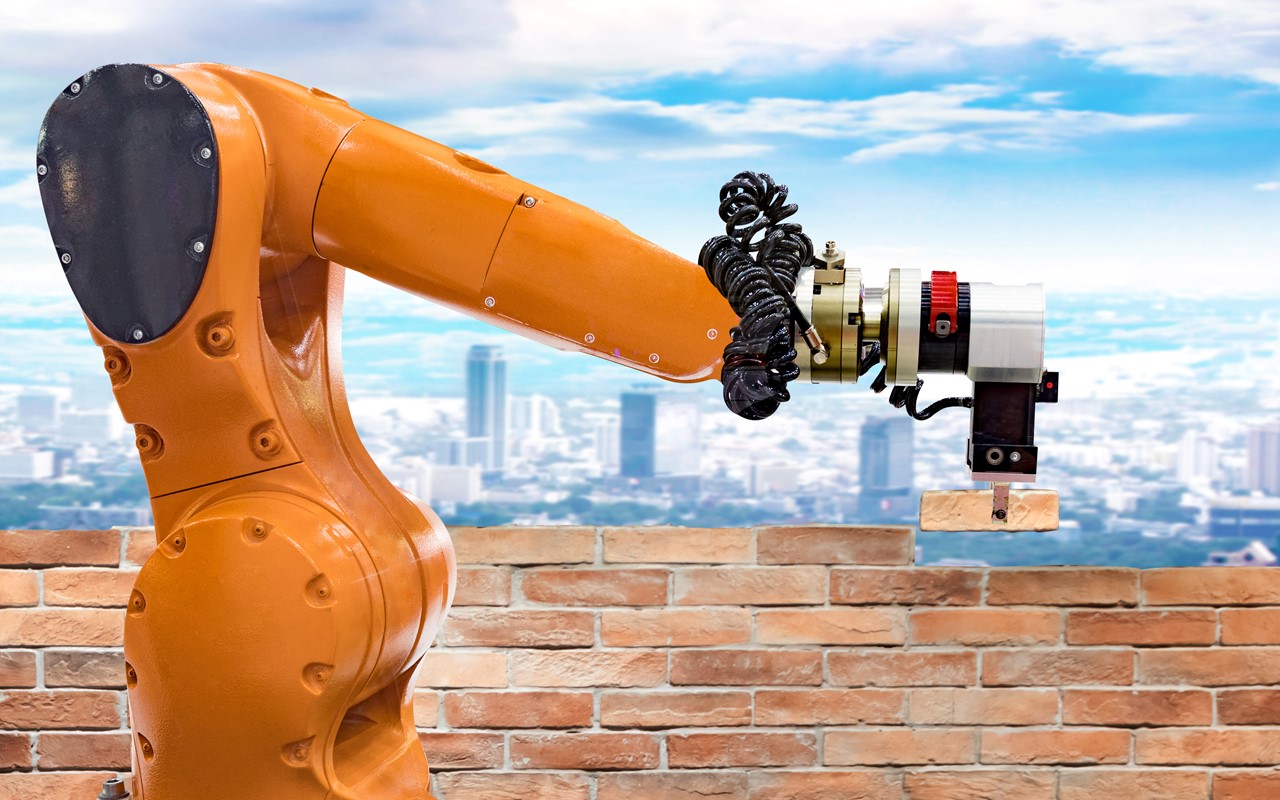

Though most people believe that they are most commonly used for modern projects, this is not entirely true. These machines have been manufactured to boost efficiency in simple projects like laying bricks. Yes, this is a very simple thing, but it is one that you should seriously consider.

It makes everything simpler, safer, and faster. For instance, all your employees will need to do is place the bricks inside the machine and learn how to use CAD programs in order to direct the machine to place the bricks in an accurate and precise way. This means that you won’t need to lay off workers, instead, use them for simpler things.

The Benefits You Can Gain

If you reached this point in the article, you probably know that you can gain various benefits from implementing androids in your facilities such as efficiency and accuracy. But, there are numerous other benefits that you can gain, including:

- You Can Cut Down Expenses – the first reason why you should consider implementing these machines is that you’ll be able to cut down costs. Since you’ll be automating various processes, you can finish projects earlier and there will be no errors that can cause you to start again. Hence, the overall expenses of your company will be lowered.

- You Can Keep Employees Safe – the construction industry is dangerous at times, which means that some of your employees can get injured while on the job. If you want to prevent this from happening, these machines are your best bet. For instance, demolition is a dangerous project and by using robots for this process and cleaning the site afterward, you’ll keep your workers safe.

- No Man-Made Errors – as mentioned, people do make mistakes. Often, these mistakes can be quite costly, especially if you are unable to save the products you manufactured. This can result in your repeating the task, which will most likely result in huge budget losses. Well, robotics can be customized and automated, which means that there will be no or fewer errors.

- Perfect For Delicate Jobs – imagine if your workers accidentally broke a large piece of equipment or glass while trying to lift it. It would be devastating, especially since it can cause downtime and additional expenses. Well, machines such as ones for glazing can do exactly that, while ensuring you that the task will be done accurately and safely.

Conclusion

As you can see, there is a wide range of ways that robots are changing the construction industry. Not only will they allow the processes to be automated, but, they’ll also provide efficiency, they can cut costs, and there is less room for human-made errors that can occur from time-to-time.

So, now that you know what these machines can help you and your construction company with, you should really not lose any more of your time. Instead, you should start thinking about what robots might suit your facilities best and start browsing online and brick-and-mortar stores in order to find the ones that will fit your needs and requirements best!