Top 4 Fleet Management Tips For 2024 and Beyond

Fleet management is one of those fields that’s undergoing rapid transformation. And if you want to have a successful program in 2024 and beyond, there are several things that you need to be doing well.

The Big Challenges Facing Fleet Management

It’s been a very interesting couple of years in the fleet industry. In 2024, pandemic-related shutdowns kept thousands of vehicles off the road and parked in storage. This obviously led to fewer maintenance issues and lower fuel costs. Then as fleets have returned to the road in 2024, a confluence of factors have created unique challenges across the board. This includes:

- Rising fuel costs. After reaching a multi-year low of $1.77 per gallon in April 2024, gasoline prices have increased throughout 2024. The current nationwide average is right around $3.19 (which is an 80 percent increase in a little over a year). This has led to bloated expense sheets and slimmer profit margins.

- Increased maintenance costs. It’s not just fuel costs that are on the rise. A new benchmark report shows that maintenance and repair labor costs are also ticking up. They rose by 2.6 percent between Q1 and Q2 2024. During that same timeframe, parts costs increased by 2.8 percent, while the cost of tires shot up by 10.7 percent. Even transmission parts rose by 9 percent.

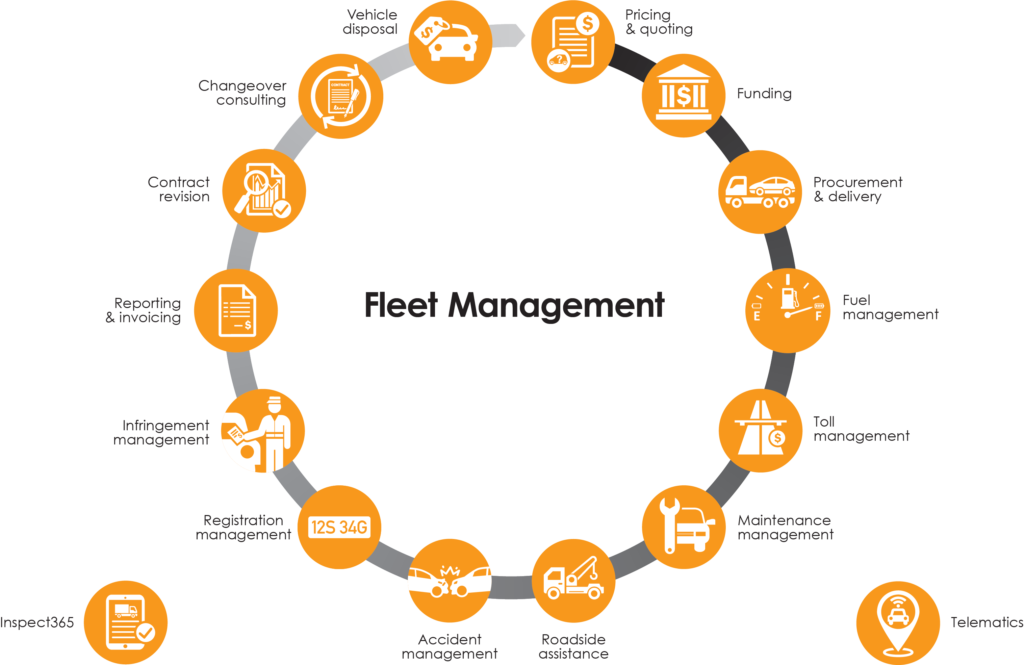

- Excessive admin tasks. As you know, managing your fleet requires a lot of administrative firepower. Most notably, it commands a ton of time and man-hours. Quoting, invoicing, communicating with customers, dispatching workers – it’s a lot! And if operational efficiency is going to be a real priority, these workflows must be optimized.

- Labor shortages. Driver shortages have been severe in 2024 and will likely continue well into 2024. This is forcing fleet managers to be more creative with staffing, routes, and promises to customers. It’s also giving existing drivers more leverage to ask for pay increases and benefits.

When you layer these complex challenges together, it’s easy to see why fleet managers are feeling overwhelmed and stressed. But these sources of friction also provide fertile ground for innovation and expansion. In other words, if you’re willing to adapt, there’s plenty of room for improvement.

4 Tips for Better Fleet Management in 2024

From a fleet management perspective, there are dozens of proactive steps you can take to lower costs, improve efficiency, and cultivate frictionless workflows that benefit the company as a whole. Here are several suggestions:

1. Streamline Purchasing

Purchasing vehicles is one of the most expensive aspects of managing a fleet. So while it may be tempting to shop around and buy vehicles at different times and from different places (in order to save a few bucks), this isn’t always the most efficient option. In the long run, you’ll discover that it’s much more cost-effective to set purchasing requirements and standardize all key aspects. This includes:

- Make and model of the vehicle

- Vehicle vendor

- Replacement parts

- Industry-specific features and upgrades

It’ll take some time to really dial in your purchase process, but you’ll eventually get a feel for what you need. Once you reach this point, purchasing will no longer be a huge time-suck.

2. Get Organized

If you’re honest with yourself, most of the stress of managing a fleet can be directly or indirectly tied back to a lack of proper organization. So if you want to be more efficient and less overwhelmed, it only makes sense that you’d improve your organization. This means getting very detailed and specific with tracking the following metrics and information:

- Fuel usage (including fueling data, locations, type, gallons, cost, etc.)

- Purchasing and leasing (contracts and warranty information on every vehicle)

- Maintenance (including scheduled repairs and unplanned repairs, dates, parts, etc.)

- Utilization (who is driving which vehicles, mileage of trips, dates, times, etc.)

- Driver licensing (certification dates, training, license information, etc.)

- Driver performance (accidents, dates, times, reports, fuel efficiency, speed, etc.)

Imagine being able to find any of this information on any vehicle or driver with a couple of clicks on a computer. This level of accuracy and visibility has the potential to totally transform your daily workflow.

3. Get Serious About Preventative Maintenance

Preventative maintenance (PM) is something that can lower long-term costs and help you get more usage out of your vehicles. But this isn’t something you want to approach manually. According to Cetaris.com, you need to automate fleet maintenance management using modern software. This will help you track and record data, while also being able to look down the line and plan ahead.

4. Rightsize Your Fleet

Having the wrong number of vehicles in your fleet is a huge mistake. The average total cost of ownership for a light-duty vehicle is somewhere between $5,000 to $8,000 per year. That means eliminating 50 vehicles from your fleet could save you as much as $250,000 to $400,000 per year.

Rather than focusing on “downsizing” your fleet, you should view it as “rightsizing.” You don’t want to get rid of so many vehicles that you put excess pressure and use on your remaining vehicles. This will lead to excess wear and tear and high operational costs. But you do want to get rid of ones that you aren’t using to the fullest.

As you think about rightsizing, try an experimental phase. If you’re thinking about getting rid of 20 vehicles, don’t liquidate them right off the bat. Instead, decommission them for a few weeks and see what difference it makes. Do you feel inadequately prepared? Do processes go on without missing a beat? Based on this “test run,” you can figure out what to do.

Propel Your Fleet in the Right Direction

Managing a fleet is a much more challenging project than most people realize. You’re responsible for coordinating with customers, drivers, etc. And in many ways, it can feel like you’re facing an uphill battle. When you prioritize the needs of one group, you’re naturally creating friction with another (and vice versa). But that’s just the way the job goes.

The best thing you can do is make sound decisions that improve efficiency while reducing costs. If you excel at these two goals, everything else will fall into place.