4 Things You May Not Know About UV Sterilization Technology

Ultraviolet (UV) light has been used as a sterilization tool for decades because it stops harmful microorganisms from multiplying. UV light breaks down the chemical bonds and scrambles the DNA, RNA, and proteins in the targeted microorganisms. The entire process only takes a few minutes, making it an efficient sterilization option for many industries.

Although UV light sterilization is widely known to be used in hospital settings, there are many different technologies that utilize UV light in additional ways. If you’re curious about UV sterilization, here are some interesting technologies you may not know about.

1. UV kitchen exhaust systems

Have you ever seen a kitchen exhaust system with a UV lamp? Adding a UV lamp to a kitchen exhaust system is an excellent way to prevent both bacteria and grease from building up inside a kitchen exhaust hood. It’s a self-cleaning technology that makes a kitchen cleaner, healthier, and safer. You can read more about this technology here.

Since UV light eliminates bacteria, this type of system also eliminates odors in commercial kitchens, which is a huge plus. If you’ve ever worked in a kitchen, no matter how small, you know it doesn’t take much for bacteria to begin emitting a terrible odor. Even just a small amount of grease can create a terrible stench in just a couple of days.

Self-cleaning exhaust systems are a blessing

Manually cleaning a kitchen exhaust hood is a big process that requires waiting until everything has cooled down to clean. This can’t always happen every day, even when it’s written into the list of daily tasks. Kitchens are extremely challenging to maintain to high standards while staying within the labor budget, so oftentimes, daily cleaning tasks get pushed to the backburner.

When commercial kitchens install self-cleaning UV technology in their hoods, it’s easier to maintain daily cleaning standards, which also means they’re more likely to pass a health inspection. Health inspections happen unannounced, and a company can fail by losing just a few points on something small like a dirty hood, making UV technology even more valuable.

In addition to preventing bacteria buildup, UV kitchen exhaust systems prevent grease buildup, which decreases the risk of grease fires. According to the U.S. Fire Administration’s Fire Incident Reporting System, grease fires account for about 2% of all commercial restaurant fires. That may not seem like a large number, but they do happen, and not all are reported.

2. Portable UV sterilizers

Today’s consumers can buy portable UV light sterilizers just about anywhere online. For example, there are handheld UVC wands made for cleaning just about anything like toilet seats, keyboards, and laptops. There are also portable UVC units you can place on a desk or table to activate when you leave the room.

Other portable devices are containers you place items inside of, like some of the devices reviewed on Forbes. For example, there are small cases that you can put your phone inside, close the lid, and run the UV cycle. Another cool invention is a water bottle cap that disinfects the water using a UVC light inside the cap. This product is perfect when you’re traveling or hiking, and you don’t trust the water source.

Precautions regarding personal UVC sterilization devices

Although these portable sterilization devices are easy to buy, it’s important to remember that you don’t want to be exposed to UV light for long periods of time. For instance, the UVC light that powers sterilization devices can cause severe burns and eye injuries. You never want to look directly at a UV light, no matter the spectrum, and you don’t want your skin exposed to the light.

This presents a challenge for home use. If people don’t read the directions, they won’t know it’s not safe to look at the light and/or stay in the room while they turn on a tabletop device.

3. Full room UV sterilization

Using UVC lamps to sterilize full rooms in hospitals has been going on for a while, but the coronavirus pandemic created a more urgent need for sterilization. Regardless, it’s a tried-and-true method for preventing new infections in hospitalized patients.

Unfortunately, many of the organisms that cause disease can live for a long time, well after the infected patient has left the room. Even when that room has been cleaned, some superbugs aren’t eliminated through traditional cleaning methods. That’s where UVC lamps come into play.

The way a whole-room device works is simple. The device is placed in an optimal area where it can shine UVC light throughout the whole room. The device is set to activate on a timer so that everyone can leave the room while it’s in operation. UVC light will bounce around and reflect into small areas like open drawers and the cracks inside of fixtures.

The process takes about a half-hour, and once it’s done, the room is safe to enter and the machine can be turned off and put away until it’s needed once more.

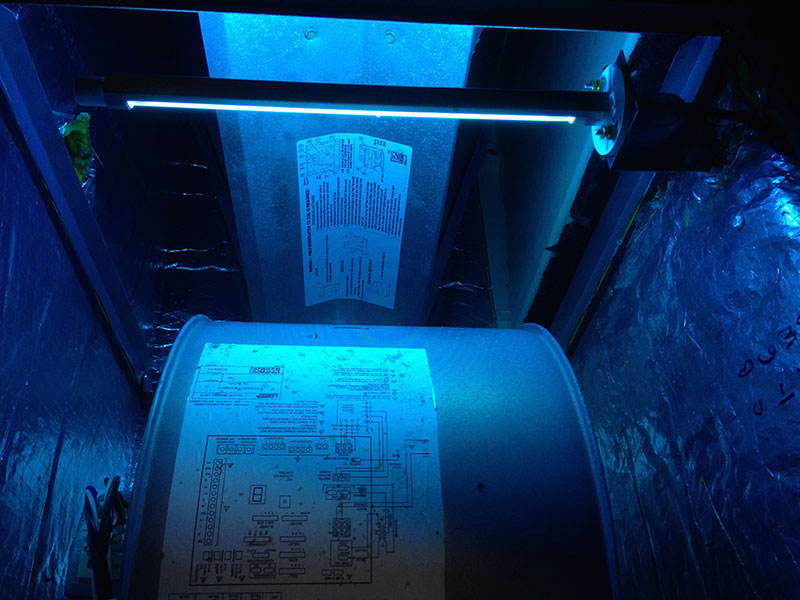

4. HVAC UV sterilization

Hospitals use more than UVB wands for wound healing and UVC devices to sterilize instruments and entire rooms. They also use UVC lamps in HVAC systems to sterilize the air by killing bacteria, including K pneumonia, VE, MRSA, and C diff. This is in addition to the sterilization units placed inside of patient rooms and bathrooms. Sterilizing the air by eliminating viruses and bacteria helps to reduce hospital-acquired infections.

With this technology, the UVC lights are placed downstream from the cooling coil to kill the larger particles, while additional lights are placed upstream of the HEPA filter to eliminate airborne viruses and bacteria.

The future of ultraviolet light sterilization is promising

Although there are already many ways UV light is being used for sterilization, there’s no doubt the future will be full of new inventions and technological improvements. The properties of UV light will remain the same, but sterilization methods will continue to improve and become more efficient over time.