What Is Photochemical Etching & How Does It Work

As technology is advancing there are many new techniques and processes that are coming in the development industry. Photochemical etching is one of them. It is a contemporary strategy that helps the different industries to carve or make small and important details on the metals.

Photochemical etching is a precision process for metal cutting and carving utilizing uniquely formed synthetic compounds to make designs on level sheets of metal. The nature of the whole process makes it highly possible to carve exceptionally precise, detailed, and many-sided highlights into a wide assortment of metals.

Photochemical machining, photograph etching, substance machining, synthetic processing, and metal drawing are an assembly cycle to create metal parts through accurate photolithography and science. This is the process through which the minute details are formed on the metals that require a high level of precision and detail.

The innovation’s special techniques set it undeniably fit the expectations and necessities of present-day manufacturing, remembering low expenses and speedy turns for tooling that, in any case, actually integrate exactness and intricacy of the plan; fast prototyping; fast circle back on creation parts orders; the utilization of extremely slight measured metals and foils, and the development of spotless, exact, unstressed and burr-free parts.

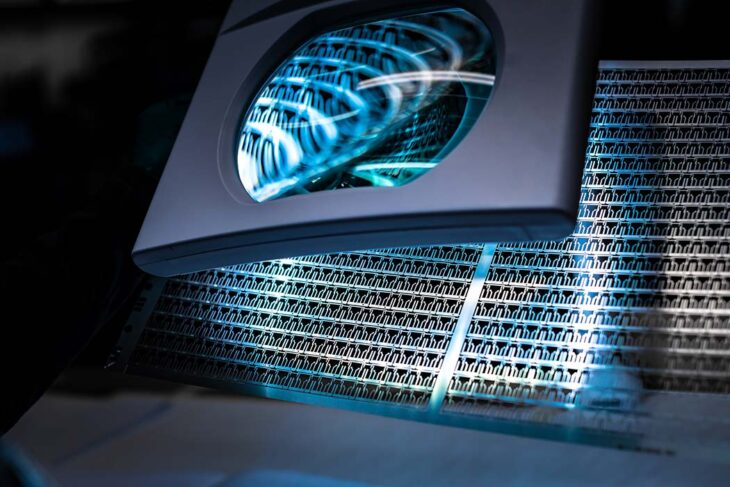

Different companies use this specific process because of the intricacy and precise design that it gives. The electronic cycle is utilized to create electronic parts. For example, PC processors have incredible intricacy and require remarkable meticulousness. The process can be used for advanced coatings, optics, plasma generators, and vacuum chambers. All the equipment and devices that need refined designs and patterns are made under photochemical etching.

What Actually Is Photochemical Etching?

Photochemical scratching, also popularly known as photochemical machining or metal drawing, is a contemporary, subtractive machining process that utilizes visual and synthetic strategies to shape metal workpieces.

The whole process takes place in an order which ensures that, at last, the final result can be perfect and no more detailing and work is required. First, the picture of a design is created on the workpiece. A solid compound arrangement or chemical is poured over the workpiece that specifically erodes and eliminates the overabundance of material from unprotected regions, leaving a perfect and sharp picture or part.

The regions to be saved or eliminated are chosen to utilize visual methods, for example, photoresist imaging. Photochemical etching can also be known as chemical etching. The chemical etching process works by ‘printing’ a part plan onto a photoresist which is overlaid onto metal. The areas of photoresist that have not been printed are taken out, uncovering the metal, which is carved away. The photo chemical etching requires precise and good equipment to achieve the desired output. Before finalizing anything, it is recommended to do good research and have a good idea about everything included in photochemical.

How Does Photochemical Etching Work?

Photochemical etching involves some steps to achieve the expected results. The photochemical etching is a delicate process and requires certain specific things to complete the whole process. Further, we will talk about all the necessary steps and procedures to be done so that the final output can be achieved.

Metal Cleaning and Printing

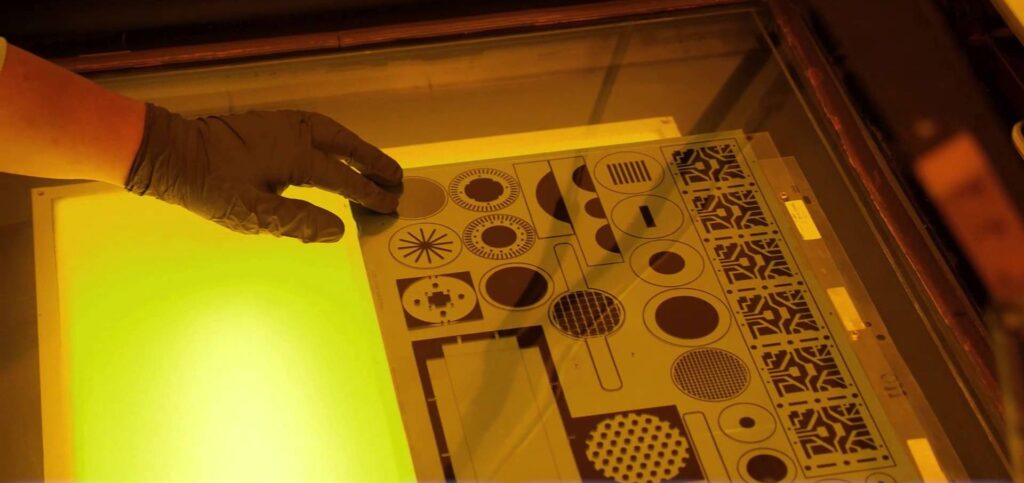

Metal part manufacture with photochemical machining is a multi-step process. It is a delicate and somewhat big process. The metal sheets or boards from which the part will eventually be cut or scratched are artificially cleaned, rolled, overlaid, or covered with a UV light touch polymer called photoresist. This ensures that the metal can be easily etched and cut out according to the need.

The metal is first cleaned properly and then covered with UV light. Now the covered metal and the photograph tooling meet. In a vacuum outline, the covered metal board is treated between the photograph veil’s adjusted top and base parts.

The vacuum is pulled in the edge compelling the tooling into private contact with the metal board. This is the whole first step that is responsible for the cleaning and preparing the metal for the further process. All these equipment and solutions are really essential for the photochemical process, and if they are not there, then the photochemical process can be taken in place.

Creating and Metal Etching

The next step is the main stage, where the main metal etching process takes place. Here the metal is processed to achieve the details and fine arrangement. It is referred to as creating; the metal board covered with specifically uncovered photoresist is showered with a compound arrangement that eliminates all unexposed, uncured, or unhardened photoresist.

During this cycle, boundaries, such as shower tensions and splash dispersion, temperature, stay time, and pH, are generally firmly checked and controlled. Toward the end, what remains are covered areas of restored photoresist that characterize the ideal parts and exposed metal stock. The whole process is done under supervision and requires the expert to ensure that the process is taking place with ease and precision.

Main Advantage of Photochemical Etching

It is quick and flexible, starting tooling to complete parts, the whole photograph drawing cycle can be finished in a maximum of 5 days. An ordinary, normal process takes almost three months, which is time-consuming. Not all companies can wait for that long. Certain operations need to be completed in less than a month, and for that, photochemical etching is the most suitable technique.

Frequently, repeated orders can be handled more rapidly, particularly assuming the natural substance is available. Model orders might be done in about fourteen days. Extra time is expected to oblige optional activities like plating, shaping, heat-treating, silk screening, gathering, or expanding surface parts. Overall it is a fast and futuristic process.

Bottom Line

Photochemical etching is a contemporary process, and it is currently practiced by a lot of big companies for etching. It is a fast and somewhat easy process that requires certain supervision and expertise, which will ensure that the expected outcome can be achieved. Till now, you must have got an idea of how photochemical etching is and how it works.