7 Steps to Create an Effective Training Program

Navigating health and safety regulations in the workplace can be quite a challenge. If you recognize the need for more training, you might still struggle to know how to put together an effective safety training program. Fortunately, there are a number of resources available to help, and following a simple step-by-step procedure will help to make the entire process much more manageable.

We’ve assembled a short, 7-step process to create an effective training program. Follow these, and the entire process will be much easier – and make a lot more sense!

Step 1 – Identify applicable standards

What is training? Training involves bringing everyone up to a certain level of knowledge or a certain standard. You can’t do that with any training program until you know what the standards are! Step 1 involves identifying which safety standards apply to you, and what you’ll need to do to comply with them fully.

What’s the best way to identify the right standards? There are two good places to start. First, if you’re a large company, there may already be safety rules and regulations established at the corporate level. Second, you can always access the industry standards set by OSHA – the Occupational Safety and Health Act of 1979. Those standards are easily accessible online here.

Finally, keep your own registry of safety standards, compiled over years of experience and helping clients plan and operate highly-effective training programs. You could also inquire to your competitors to see what training standards they adhere to and if they have any recommendations towards courses. While training for your specific field may be specialized, OSHA standards are the required base for all training. Assess your training needs; perhaps this is an opportunity for you to improve in a certain area of your business with a little extra training.

Step 2 – Compile a list of courses needed

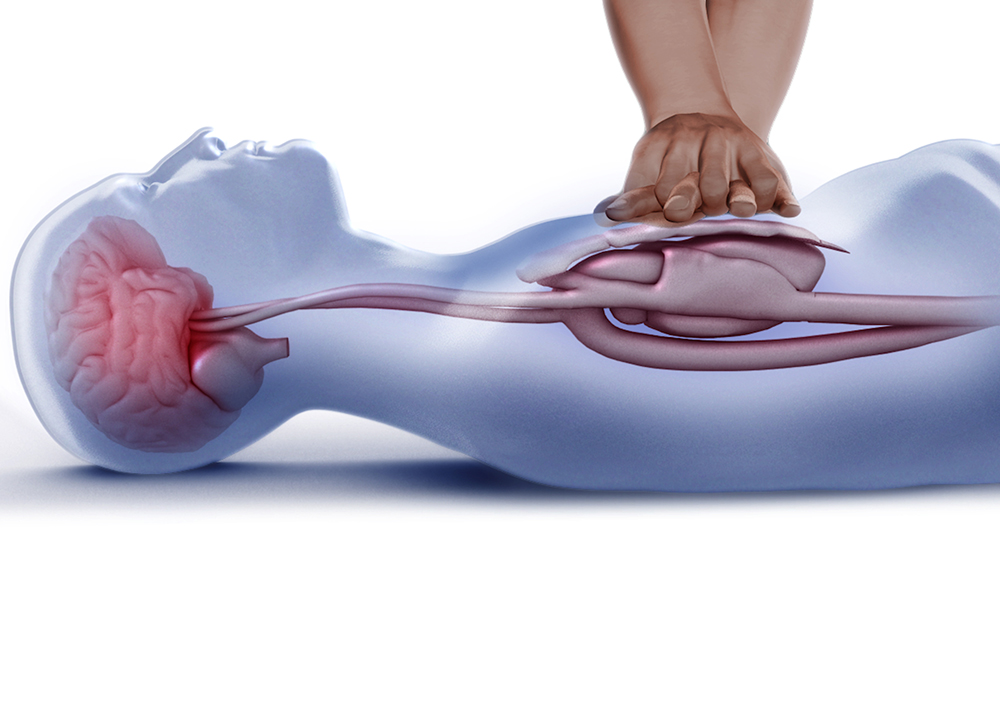

Once you’ve compiled and determined which standards you’ll need to meet, you can begin to compile a list of the necessary courses. Those can be highly specific courses, such as Skid Steer Training, or courses designed to deal with particular risks, like Asbestos Training or Confined Space training. Whatever course you’ll need, it should be arranged so you and your employees will be fully equipped and prepared to meet any safety standard.

Your training may be comprised of three different types:

Classroom training – where the employee learns in a classroom setting. This may be done in your office or offsite, depending on the training.

Online learning – where the employee learns from a video online and may have to answer questions on a computer afterwards.

Blended learning – a combination of classroom and online learning.

Each type of training has its pros and cons, so research the courses to see which is best.

Step 3 – Assign the frequency of the training by job type

Not all training is one-and-done. CPR and First Aid courses typically require a refresher course every year. And of course, any new employees that are brought on will require the basic safety training for their job. Health and safety training companies and you should arrange the frequency of the different courses to keep your employees up-to-date and safety conscious.

As you ease into a new training program, plan your courses for the year and then subsequent years. Additionally, ensure that the courses you’re assigning for the future are up to date. You don’t want to be using courses that are 15 years old, 14 years down the road when you should have updated them several times over.

Step 4 – Schedule the courses

After determining the standards, compiling the course list, and setting the frequency, now comes the hard part: actually scheduling the courses. Some infrequent courses might simply be scheduled as-needed, while others might be much more frequent. Ensure that training schedules are smooth, efficient and take care not to overwhelm the trainees with too much information.

For new employees, there is always a bit of course overload at first, so it may be best to spread out any unnecessary training until a new employee understands the requirements of the job. Plan for new employees to have basic, necessary training the first week and the following weeks can have the remaining safety training as needed.

Step 5 – Monitor Compliance with participation and standard changes

Compliance is a major step of an effective training program. It’s not enough to train your employees and then throw them to the figurative wolves – you’ll need to make sure they’re following the correct procedure. You should be aware of compliance regulations. And of course, sometimes the rules change; you should be updated as government and industry standards change and know if and when you need to update your safety training.

Step 6 – Get feedback on ways to improve

Every course is only as good as its teacher. Feedback on how to improve courses and ensure a fully professional and high-quality atmosphere for your safety training program should always be provided. If you’re rolling out a new course, it may be helpful to require feedback after the course is completed, to ensure that your employees who already have a good grasp of health and safety agree with the content.

Step 7 – Track your safety performance from before and after

Safety training is absolutely necessary, and it’s always beneficial to see evidence of that in safety records. Tracking your job safety performance is a great way to see first-hand benefits from your safety training program, and your health and safety company can teach you the best ways to see that improvement.

One worry that employers have about health and safety training and awareness is that employees won’t engage fully. However, ‘health and safety has, at least to a large extent, solved this problem’, says David Rowland, the head of marketing Engage EHS. This is because the process is much more social and, if you must, you can measure your employees’ engagement in the process.

Together, these seven steps help to ensure that your safety training program is the highest quality, keeping your workplace safe and hopefully minimising safety risks to your employees and to your bottom line. Ultimately, safety training seeks to keep your employees safe and good health, which is necessary to running a safe and healthy business.