Emission Control Scrubber: Advancing Air Quality in Industrial Settings

An emission control scrubber stands as a forefront technology in the pursuit of cleaner air in industrial environments. This advanced system plays a pivotal role in mitigating pollutants emitted during various industrial processes, contributing significantly to environmental sustainability.

Scrubber Mechanism

The fundamental mechanism of an emission control scrubber involves the use of chemical reactions to neutralize and remove pollutants from industrial exhaust streams. Typically, a scrubbing solution, often composed of alkaline substances, reacts with acidic gases or particulate matter, resulting in the formation of harmless byproducts.

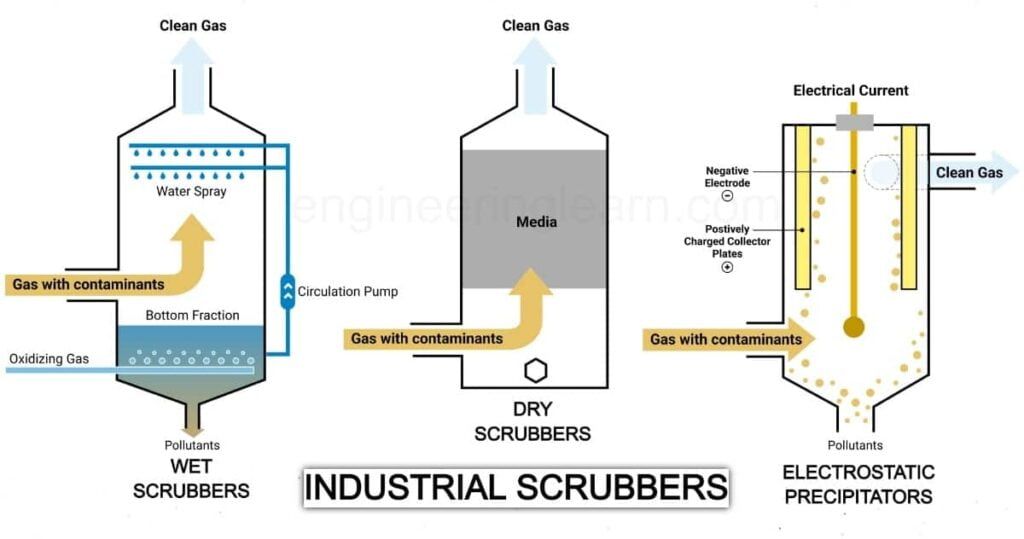

Types of Scrubbers

There are various types of emission control scrubbers tailored to address specific pollutants. Wet scrubbers, dry scrubbers, and hybrid scrubbers offer versatile solutions for industries with diverse emission profiles. Each type exhibits unique advantages, ranging from high efficiency in particulate removal to the effective neutralization of acid gases.

Particulate Matter Removal

Emission control scrubbers excel in the removal of particulate matter from industrial emissions. By utilizing inertial impaction, diffusion, and interception mechanisms, these scrubbers efficiently capture and eliminate particles, contributing to improved air quality and reduced health risks for workers and surrounding communities.

Acid Gas Neutralization

In industrial processes generating acid gases, emission control scrubbers provide a robust solution for neutralization. The scrubbing process chemically transforms acidic components, such as sulfur dioxide, into non-hazardous compounds, ensuring compliance with stringent environmental standards.

Energy Efficiency Considerations

Modern emission control scrubbers are designed with a focus on energy efficiency. Advanced technologies, such as regenerative systems and optimized process control, minimize energy consumption, aligning industrial operations with sustainability goals.

Applications Across Industries

Emission control scrubbers find wide applications across industries such as power generation, chemical processing, and manufacturing. Their adaptability to different emission sources underscores their versatility in addressing environmental challenges in various industrial settings.

Advancements in Scrubber Technology

Advancements in Scrubber Technology

Ongoing research and development continue to enhance emission control scrubber technology. Innovations include the integration of smart sensors for real-time monitoring, improved materials for increased durability, and precision control systems for optimal performance.

Advantages of Emission Control Scrubbers

Emission control scrubbers offer several key advantages that make them a preferred choice for industries aiming to reduce their environmental impact. These benefits span various aspects of industrial operations and environmental protection.

One notable advantage is the ability of scrubbers to operate effectively across a wide range of pollutants. Whether it’s particulate matter, acid gases, or other harmful emissions, scrubbers can be customized and optimized to tackle specific contaminants efficiently. This versatility reduces the need for multiple pollution control systems, streamlining the overall process and saving costs.

Another significant benefit is the immediate impact on air quality. Emission control scrubbers work in real-time, ensuring that harmful pollutants are removed from industrial emissions before they are released into the atmosphere. This not only protects the environment but also safeguards the health of workers and neighboring communities, contributing to a safer and healthier working environment.

Environmental Regulations and Compliance

The implementation of emission control scrubbers in industrial settings is closely tied to the ever-evolving landscape of environmental regulations. Governments and environmental agencies around the world have established stringent standards to curb industrial emissions and protect air quality.

Emission control scrubbers play a pivotal role in helping industries meet these regulations and maintain compliance. By effectively removing pollutants from industrial exhaust streams, scrubbers enable companies to adhere to emission limits and avoid costly fines and legal ramifications.

Conclusion

In conclusion, emission control scrubbers represent a crucial component in the contemporary landscape of industrial pollution control. Their efficiency in particulate matter removal, acid gas neutralization, and adaptability to diverse industries positions them as integral tools for promoting cleaner air and sustainable industrial practices.