8 Reasons Why Laser Cutting Is A Perfect Side Hustle Idea

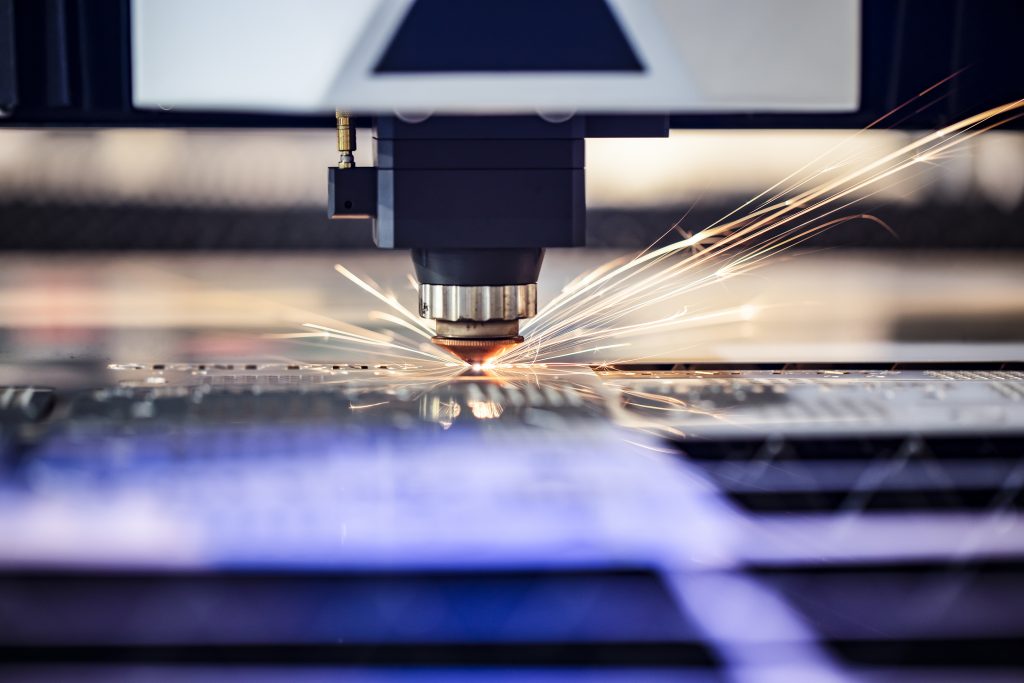

Laser cutting is a conventional method of machining wherein you can cut different materials with the help of a concentrated and coherent stream of light known as lasers. The material is continually removed during the process. The laser beam which is used to cut the metals is usually controlled digitally using a CNC ( Computer Numerical Control) machine. Many people have started business in this field because of the multiple advantages this method provides them.

How does laser cutting work?

Now that you know the basic definition of laser cutting, let us understand how it works. In this process, a powerful laser beam is focused on the material through a CNC machine or optics. In this method, the motion control system is used to track the G or CNC code of the shape or pattern that is to be cut. When the laser beam falls on the metal, it melts and evaporates. The surface you get after the completion of the process is of very high-quality.

What are the benefits of starting a side business of laser cutting?

Many people want to start a side business to generate more money apart from their regular income source. Laser cutting business is great for such people because it has a lot of potential to grow in the future. Some other benefits that explains why laser cutting is a perfect side hustle for you are given below:

1. Low cost:

Probably the best advantage of a laser cutting is that the costs required even for short term projects are very low. This is because this method utilizes no sort of tooling that should be exceptionally assembled or modified to perform the tasks. It likewise doesn’t have physical removing surfaces that are prone to wear and tear.

To make a component using this process, all you want is a material to cut, a laser cutter, and a schematic which can be stored into the PC. This helps in reducing the overall expenses even for small scale projects as compared to other conventional machines or manufacturing. Laser devices likewise have less mechanical moving parts, which reduces operational and maintenance expenses.

2. High productivity:

High travel velocities and profound penetration both add to high efficiency of laser cutting methods. Normal travel speeds that are required to cut metals using this process is 10 meter per minute. More slender metal sheets ranging between 0.1 to 2 mm are commonly cut quicker while thicker sheets are cut at lower speeds.

This speed is very high as compared to other conventional machines that have speeds ranging between 0.25 to 2 meter per minute. Likewise, since laser cutting is a non-contact process, it doesn’t just have lower apparatus costs yet in addition requires very short loading and unloading time. Co2 laser cutting machines provide the highest productivity.

3. No expertise required:

If you have an inventive mind, you could produce your own items and designs without any professionalism or experience. All things considered, you needn’t bother to have an artistic bone in your body to begin a laser cutting business. You can depend completely on programming and pre-made designs to make unique and trendy objects. If you don’t have a big budget to start a business, you can pay attention to engraving designs on existing items only.

4. Energy usage:

Because of the advancement in technology, laser cutting machines utilize less energy than other cutting techniques. Truth be told, laser cutters will regularly use around 10kW of energy during the procedure, while other methods will use around 50kW of energy. As business owners hope to work more intelligently and utilize less energy, to save money and manufacture environmentally friendly products, laser cutters can help make progress toward this objective. This is an incredible method for reducing energy consumption costs.

5. Can handle complex jobs:

There is no work that is excessively complex for a laser cutting machine. This powerful method can be utilized to chip away unwanted material from a narrow segment of material and makes almost no distortion or warping the region being cut. With the proper plan, a laser shaper can be utilized to rapidly and effectively make even the most exceptionally complex calculations and cuts with unrivaled accuracy and great tolerance levels.

6. Versatility:

Multi-axis lasers permit you to do a wide scope of tasks. They can cut materials of every single type and thicknesses. They can cut both basic and complex designs without any problem. This method can cut a wide assortment of materials including metals, amalgams, precious stones, plastics, woods, and glass. Laser cutters can make complex shapes in these materials in a short time span. Their accuracy and precision is better than other conventional methods.

7. Less waste:

At the point when you utilize a laser shaper for cutting different materials, only a small amount of waste is generated. This makes this procedure very different from other conventional processes that produce a lot of waste. This helps in maximizing the use of materials. The expense of production also decreases when there is less waste and maximum use of materials.

8. Avoid Damage:

One more benefit of using this process for cutting materials is that there is less damage. Many individuals believe that it is unavoidable to prevent damage to materials. This is because of the heat that is produced during the cutting process. You should take a note that heat affects only a little region of the material and doesn’t influence the tolerance in laser cutting procedures. The speed at which the laser slices through sheets is very fast, so cutting takes less time. In this way, makers can undoubtedly abstain from distortion and warping.

To Sum Up

Laser cutting process is a highly accurate method of cutting different materials. It is not very expensive to maintain and also produces very less waste, which is why many people have opted for this idea for starting their business. Check out the other advantages mentioned above to understand how it will be beneficial for you to start a laser cutting business as a side hustle.