Warehouse Safety Tips for Ecommerce Businesses

Workplace safety is an essential aspect that ecommerce businesses need to think about. Workplace accidents cause online businesses with warehouses for fulfillment millions of dollars in combined costs each year. This amount includes insurance payouts, worker claims, medical bills, employee absences, and more.

Most of these accidents take place in warehouses. While factories and other high-risk facilities have greater risks associated with them, they also have more comprehensive safety protocols and training. Warehouses, on the other hand, have often shied away from proper worker safety training to cut costs. Simply adding barriers like those offered by the crowdcontrolcompany can be a great help in ensuring worker safety.

This short-term cost-cutting leads to huge costs later down the line.

By using simple tips and safety protocols, you can increase worker safety in your warehouses. Not only will this reduce costs in the long term, but it can also positively affect worker morale and productivity.

Here are a few simple tips to increase safety in your business’s warehouses.

Make A List of Problem Areas

You can’t fix the problems in your warehouses if you aren’t even aware of where the problems are. Do a safety audit for your warehouses and see where issues keep cropping up regularly, which areas present the greatest risks, and which areas need improvement.

Since this can be a tall order to start on, you can visit OSHA’s website, which highlights all the common problem areas when it comes to workplace injuries. The list is always kept updated on their website, but here are some of the common problems as follows.

- Wet Floors

- Exits

- Forklifts

- Electrical Wiring

- Mechanical Transmission Systems

You can find the full list on OSHA’s website.

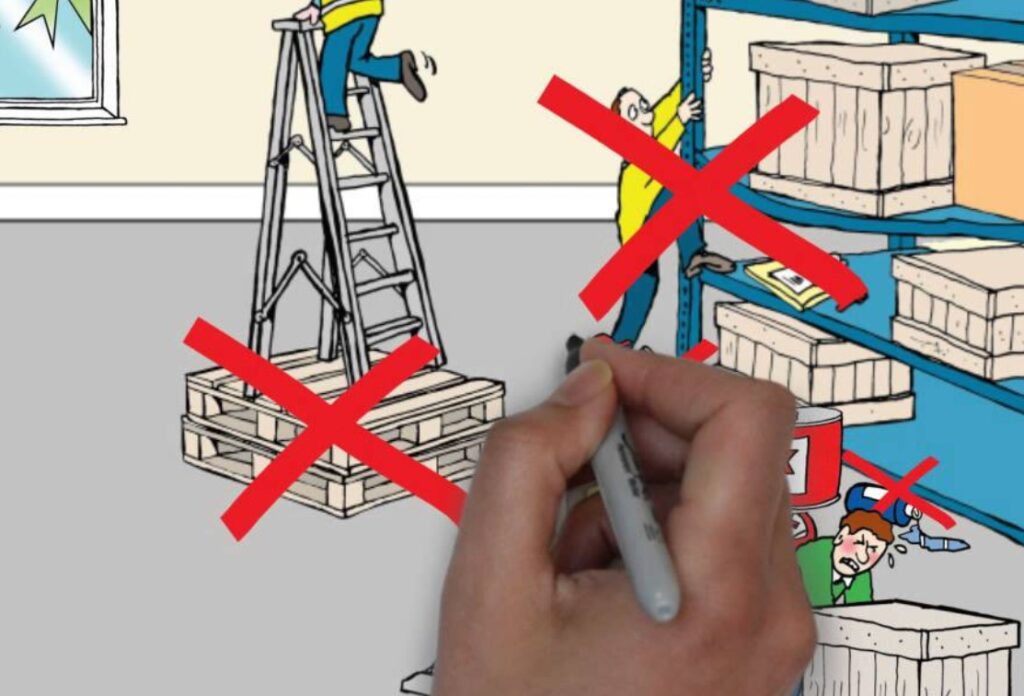

Providing Safety Information

After recognizing the problem areas in your warehouse, you need to give proper safety information for those areas. By providing crucial safety information, your warehouse workers will be able to better avoid any potential chances of accidents and injuries.

Safety instructions should be topical, easy to comprehend, easily accessible, and present in the right locations. Simple visual posters like reminders to wear hardhats or to close off hazardous terrain with retractable belt barriers are some examples.

Do keep in mind that this information is just part of the overall safety information that your workers need. This information is on the site where issues can crop up. It doesn’t represent the entirety of safety training that your warehouse workers should receive.

Provide Clarity

Your employees need to know where everything important is in their warehouse even before an emergency strikes. Every exit, emergency exit, entrance, fire extinguisher, or such equipment needs to be marked.

You don’t want your warehouse workers struggling to find all of this information when an emergency is occurring. You want your workers to be prepared to react properly whenever there is any kind of emergency in the warehouse.

You can signal out exits and other important equipment by using highly visible signs and barriers to immediately signal their location.

Deal With Safety Hazards

Based on the list of the problem areas in your warehouse, you need to start working to eliminate them. The sooner you fix a problem, the fewer chances it has to grow into something bigger and more dangerous.

That’s why you need to be conducting safety audits in your warehouse regularly. This lets you catch any potential risks that may have appeared since your last check.

If you can’t immediately remove a hazard, then you try to highlight them as clearly as possible. Use retractable belt barriers, post signs, send your workers memos. You need to make sure that everyone is aware of any potential hazard that might be lurking in your warehouse.

This is even true if you are working on removing a hazard. Make sure that the area is closed off to the rest of the workers while the hazard is being eliminated. Use barriers and signs to prevent other workers from getting too close.

Provide Necessary Safety Equipment

Also, to highlight hazards, you need to give your workers the correct safety equipment for the job. You can’t constantly be looking out for employees, and some accidents are just not preventable or foreseeable.

For these cases, safety equipment is essential. It can significantly reduce the amount of harm any person suffers. Common safety equipment like hardhats, high visibility vests, and whistles are some of the basic equipment that every warehouse worker needs access to.

Other important safety equipment includes first aid kits, fire extinguishers, eye protection, etc.

Safety equipment doesn’t just extend to equipment that your workers have to actively wear or use. Electric surge protectors, automatic cut-off switches, washing stations, alarm stations, and more are equipment that is immovable and built into your warehouse but just as essential.

Provide Safety Training

All of the equipment and warnings won’t do much if your employees are not trained to work safely. If your worker doesn’t know that he shouldn’t head into an area closed off with a retractable belt barrier, then there is no point in the barrier is there.

Similarly, it won’t help your worker if he doesn’t know how to wear a hard hat securely, no matter how many hats you are providing to him.

Your workers should regularly be trained and refreshed in proper safety protocols. They need to be taught how to work safely in your warehouse, how to minimize risks. Even simple things like teaching proper lifting techniques can prevent countless injuries in your workforce.

They especially should be trained in how to use special machinery. Workplace accidents due to special machinery and heavy machinery are one of the most common causes of fatal accidents in the workplace.

Summing it up

Your workers should also be taught how to use the safety equipment that you are providing them. A fire extinguisher isn’t of much use if no one knows how to use one, for example.

Apart from training, you should communicate with your workforce about what kind of safety procedures that you have in place. A worker who has been trained in the proper safety protocol will be less likely to do things that can cause him unnecessary harm.