4 Reasons to Consider a Temperature Mapping Project in 2024

2020 was a strange year for millions of businesses. Some businesses were unexpectedly booming. Others suddenly slowed or simply closed.

Coming back from the global shutdowns or business overdrive has created a necessity most of us wouldn’t have predicted: the need to temperature map storage and shipping spaces.

What is temperature mapping?

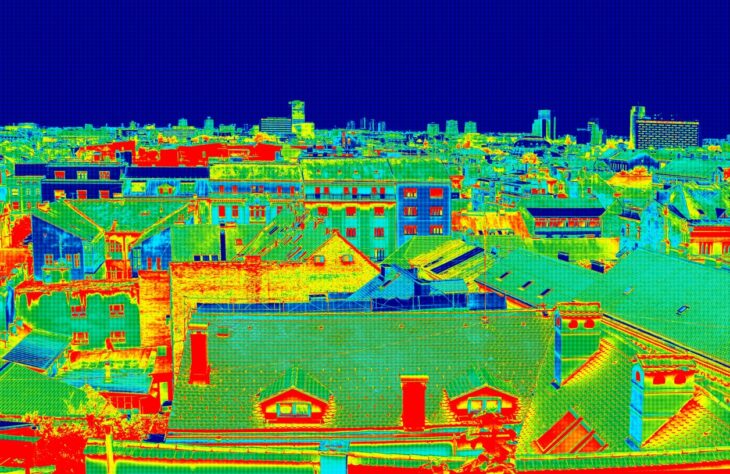

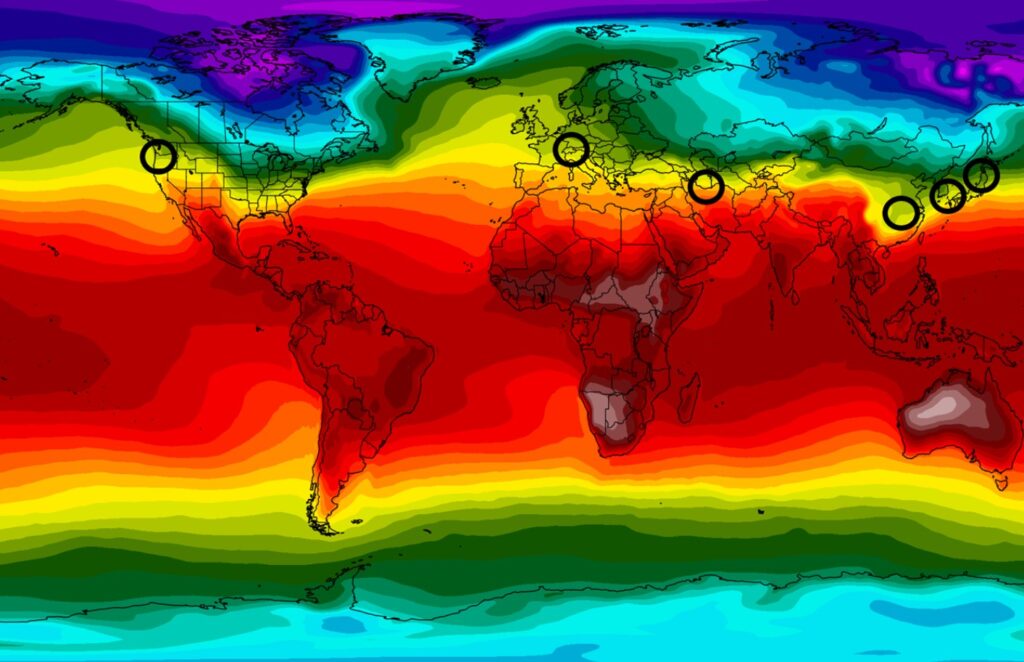

In its simplest form, temperature mapping simply takes the temperature of an area in multiple locations to see how those temperatures vary. We’re all familiar with temperature maps of the oceans or the air that show where it’s warm and where it’s cold.

For businesses, this type of temperature mapping often takes place in storage areas, particularly refrigerated spaces, trucks and rail cars, and in processing plants and laboratories. Any place where maintaining a steady temperature is vital, a temperature map can help ensure that every corner has the same temperature. This can apply to much smaller, but vitally important spaces, such as an autoclave where inadequate temperatures can create a medically dangerous situation.

The World Health Organization does an excellent job of summarizing the importance of temperature mapping in new installations:

All new temperature-controlled storage areas must be temperature-mapped as part of a fully documented verification process, before the installation is commissioned and handed over by the installer. Until this has been done, it is not safe to store TTSPPs in such areas.

The temperature mapping procedures should:

- Demonstrate the air temperature profile throughout the storage area when empty and in a normal loaded condition;

- Define zones which should not be used for storage of TTSPPs (for example areas in close proximity to cooling coils, cold air streams or heat sources); and

- Demonstrate the time taken for temperatures to exceed the designated limits in the event of power failure.

What you can learn from temperature mapping

A temperature map will show you where you have hot and cold spots. You’ll have a visual representation of the temperature differences in, for example, your cold storage or your laboratory.

Using this information, you can make adjustments to airflow and cooling/heating systems to create more uniformity in the space.

When is temperature mapping important?

The recent COVID-19 pandemic brought to light the importance of reliable temperatures. The San Francisco News wrote, “The vaccines that are currently approved for use in the U.S. – from Pfizer, Moderna, and Johnson and Johnson – need to be stored at anywhere from normal, refrigerated temperatures to an ultra-cold deep freeze in order to maintain their effectiveness.”

Suddenly, refrigerators in pharmacies and the cooling ability of delivery trucks came into the spotlight. These places need to reliably maintain extremely low temperatures for extended periods. Otherwise, the all-important vaccines might be less effective or even useless.

Even if what you’re storing isn’t as vital as the COVID-19 vaccines, steady and reliable temperatures across your manufacturing, storage and shipping spaces is important for making certain that your goods and/or produce are delivered in the best possible condition.

Four Reasons to Conduct a Temperature Mapping Project

Why should you do a temperature mapping project in your spaces?

- Protects Your Products and Revenue – Loss of products costs American businesses billions every year. When we think of product loss due to temperature, we most often think of perishable foods, but with today’s sensitive electronics, very high or very low temperatures can cause the loss of entire shipments. By doing a temperature map of storage and shipping spaces, you’ll be able to find the hot and cold spots that might compromise your products if overlooked. While you might not lose an entire shipping container, the extreme temperature spots can be problematic and cause the loss of at least some of the equipment. Other spaces, like bakery proofing rooms, need to have even temperatures or the final product will be inconsistent. Using a temperature map, you can see that the entire room is the right temperature and that your recipes will proof correctly.

- Keeps You on the Right Side of Regulatory Compliance – It’s just your luck. The inspector shows up to test the temperatures in your freezer units. She takes out her infrared thermometer and starts testing the space. As she moves around, she finds several locations that are out of compliance. Suddenly, something that might be solved by moving a rack of shelves to change the airflow is a violation of code. Knowing that the entire space is up to code, not just the areas right in front of the cooling or heating unit, will make an inspection much less traumatizing and nerve-wracking. Helps You Understand the Impact of Your HVAC System – In many businesses the HVAC unit is among the most expensive to purchase and operate. Knowing how your HVAC is performing will let you know that you’re not wasting money when trying to efficiently heat or cool a space. In some spaces, the HVAC will run constantly, but doesn’t seem to be doing its job correctly. This can be caused by something as simple as an obstruction that can be slid out of the way or you might need new vents or a stronger system.

- Gives You a Plan for Your Monitoring Needs – According to Dickson, setting your organization up for future monitoring success is one of the main benefits of a mapping project. Knowing the problem locations allows you to place monitors to make sure you don’t encounter a problem again. This keeps your spaces in compliance and your HVAC providing you with the most efficient results.

When to Do a New Temperature Mapping

Certain situations warrant a new temperature map:

- New installation – As the WHO quote above describes, new installations should have a complete temperature map before use.

- Movement of equipment – If you move shelves, doors, or any other large furniture or appliances, a new map will ensure that you didn’t create new hot or cold spots.

- New equipment – Any new equipment, even something as simple as a new belt in an air conditioning unit, can create temperature imbalances.

- Changing outside conditions – Many places in the world are seeing summer temperatures rise quickly. This can change the effectiveness of cooling units.

- Reopening – After the closures and slowdowns of 2024, it’s important to guarantee that equipment comes back online properly. A temperature map will prove that your temperature sensitive spaces are ready for use.

Setting up a permanent data logging system will provide you with ongoing temperature monitoring. While not as in-depth as a temperature map, it ensures compliance and prevents spoilage.

Knowing what your spaces need starts with a comprehensive temperature map. With that information, you can make decisions about the future and ensure that your spaces are in compliance at all times.