Bearings Unveiled: Tips to Help You Choose and Compare for Optimal Performance

There are so many things we can and should do in order to make the most out of the machinery we operate on a daily basis. Of course, it all starts with proper maintenance, but there are also so many things we can and should do besides that. Namely, one of the biggest problems people face is picking the right bearings, as this component is one of the essentials, which is just one more reason why, before making any decision regarding which one to go with, one should always explore all the possible options. Now, since there are so many specific requirements and types, we will go through tips to choose the best bearings for optimal performance of the machinery you operate with.

Types and housing units

There are so many types to choose from, which is probably the biggest reason why people don’t really know which one to go with, depending on what they need it for. Of course, the lack of info on this topic is also a big problem, as there aren’t that many specialized sites where you can find precise info and guides regarding bearings, types, and differences, not to mention how to use them. Another important segment is housing units, which also isn’t something that one can easily find the right info about online. With that settled, let’s check how to get ready-to-install bearing with housing.

There are two groups

Since there are so many types, it’s easy to get confused, which makes picking the right one more challenging, but once you learn that, in most cases, you will go with the one with a rolling element, it makes the choice much easier. Namely, there are two main groups, the ball and roller bearings, but they have several sub-categories with specific features that you can use for different purposes.

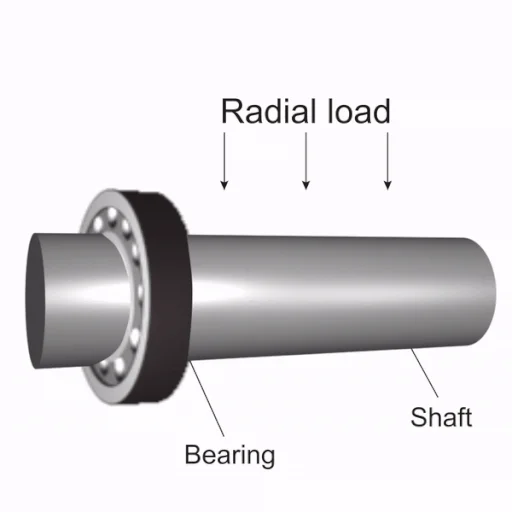

The importance of bearing loads

The first tip on how to choose the right bearing is about bearing loads because of its load capacity, which is pretty important. Once we have that info on how much capacity this load can take, it shortens our list of which of them is the most suitable for our needs. Understandably, there are three main categories of bearing loads, and depending on the specifics of why you need one and what type it is, you can choose between radial, axial or combination.

Ball bearings

Since they are designed with spherical balls (hence the name), they are ideal for spreading loads for medium-sized areas. This doesn’t mean that they cannot be used to cover larger areas, but they are definitely the most efficient for small to medium-sized surface areas.

Roller bearings

On the other hand, we have roller type, which, unlike ball bearings, is more for covering larger areas. Understandably, they can be used even for medium-sized surface areas, but using them for small areas is not recommended.

Higher efficiency

Now that we have covered that, we need to focus on the essentials – how to make the most out of your machinery, efficiency-wise. Everything in this line of work is about efficiency and precision, which makes the goal of making the most out of your machinery pretty understandable. There are two crucial factors – accuracy and speed at which the machinery operates. Because of that, for machinery and equipment that works at high speed, one should go with precise roller bearings. The reason for that is simple – you want to minimize the room for making any mistake, and since precision is of utmost importance, this roller bearing type is the best one.

Of course, this choice isn’t that easy, as we want to match the maximum tolerance with the special requirements of the machinery we use in order to reduce the room for making any mistakes. The most common one is premature wear and reduced efficiency, which is not something anyone wants, so when picking bearings for high-speed machinery, keep in mind that you should go with the type that grants the most precision and suits the requirements of the machinery you operate the most.

Lubrication

Like with all other things machinery-wise, the only way to prolong the life of your machine is with proper and regular maintenance. Now, every machinery and equipment has different rules regarding maintenance, but proper lubrication is the main and most important tip for roller bearings. The only unknown here is whether to go with oil or grease lubrication, depending on the machinery one has at hand. But, once one decides on lubrications, it helps make the right decision regarding roller bearings, as not every bearing works well with certain types of lubrication.

So, in order to prolong the bearings’ lifespan, make sure to go with the type that works ideally with your preferred type of lubrication, but once again, regular and proper maintenance is also of vast importance since the goal is to prevent premature wear. It’s needless to say how costly any mistake made here can be, as any failure, breakdown, or malfunction can cost thousands of dollars.

Don’t overlook the working conditions

We use various machinery for various tasks, and more importantly, we use it in various conditions, which is why this is another factor we need to keep in mind when picking bearings. Moisture is probably the most common problem, as this is something that happens regardless of the environmental conditions where our machinery operates. On the other hand, extreme temperature is something that can play a huge role in how good machinery performs in the long run.

All this just means that depending on the working conditions under which our machinery operates, we need to spend even more time maintaining it. Understandably, roller bearings are ideal for such conditions, as regardless of how extreme conditions are, these types of bearings work great because they are specially designed for such purposes. Namely, they can withstand almost any environmental condition, which is also one of the biggest reasons why people go with roller bearings in the first place, and you can find the best one at https://www.tuli-shop.com/bearings/ball-transfer-units.