What Industries Can Benefit from Photo Chemical Etching?

Many different industries can benefit from photo chemical etching. This process is a great way to create precise and accurate metal parts for various applications.

This post will discuss some of the most common industries that use photochemical etching services. But first, let’s look at some of the benefits that this method offers.

Benefits of Photochemical Etching

- Precision: The etching process can be very precise, allowing for intricate designs to be created.

- Flexibility: Photochemical etching is a versatile process that you can use to create a wide range of products.

- Speed: Etching can be completed quickly, making it an efficient manufacturing process.

- Cost effective: Etching is cost-effective to produce precision parts and products. It also helps to reduce waste material.

5 Industries that Can Benefit from Photochemical Etching

1. Aerospace

Aerospace is a growing industry that can benefit from photo chemical etching. Parts for airplanes and spacecraft need to be lightweight and strong, making photochemical etching an ideal manufacturing process. In addition, the high level of precision required in aerospace parts means that photo chemical etching is often the best option.

2. Military

Another industry where photo chemical etching is extensively used is in the military. One common use is for creating stencils and masks for camouflage uniforms. You can also use the process to create precise designs on weapons and other equipment. Additionally, photochemical etching can be used to create medical devices and implants. Using photochemical etching instead of traditional manufacturing methods, the military can save time and money while still achieving high-quality results.

3. Medical

Photochemical etching is used to create custom medical implants and devices in the medical industry. Using a photo-etched mold with extreme precision and accuracy. This results in a product that is fit for the individual patient, which reduces the risk of creating the implant or device of complications and increases the surgery’s success rate.

It is also used to create prosthetic body parts. These prosthetics are often highly complex, with moving parts and intricate designs. The level of detail achieved with photochemical etching means that patients can have realistic-looking prosthetics that are fitted precisely to their body shape and size.

4. Computer and Hi-Tech Industry

The computer and hi-tech industry can benefit from photochemical etching because it offers a fast, low-cost way to create prototypes and short-run production parts. Photochemical etching is also ideal for producing very small or intricate parts that are difficult to produce using traditional manufacturing methods. Often when there is a need to recalibrate sensors for UV lights, the parts needed will be photo chemically etched.

5. Automotive

The automotive industry can significantly benefit from photo chemical etching. This is because it can help create more intricate and detailed designs on car parts. Additionally, it can also help create lighter and stronger car parts, which can improve the fuel efficiency of cars. As a result, the automotive industry should consider using photochemical etching to improve their products.

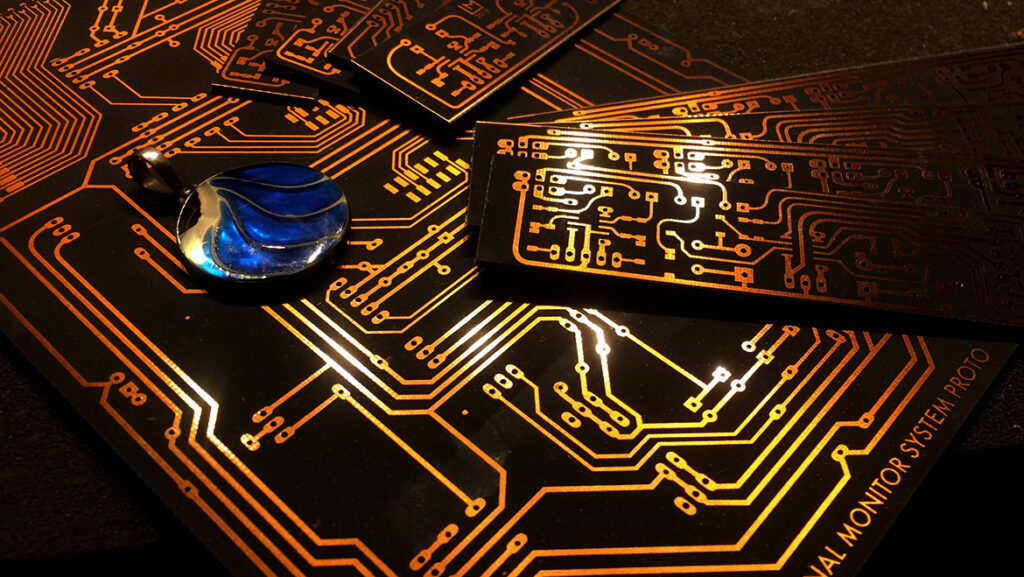

6. Audio and Visual

In the audio industry, circuit boards are used in a wide variety of products, including amplifiers, receivers, tuners, and more. Photo chemical etching is a great way to produce these boards quickly and accurately. The same is true for the visual industry. Circuit boards are often used in LED lighting, displays, and other electronic devices.

Conclusion

Overall, photo etching, or more specifically photo chemical etching, is an excellent process for industries that require precise and intricate details. The precision of the etching can create products with complex designs and features that would be difficult or impossible to produce through traditional manufacturing methods.